admin

admin  January 21,2026

January 21,2026

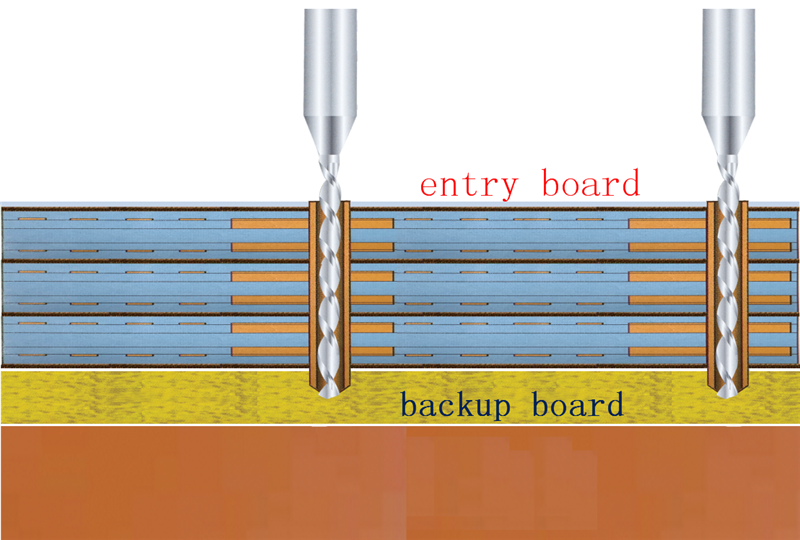

The Backup board for PCB drilling is placed under the processing board during PCB mechanical drilling, which is used to protect the processing board and drilling machine, penetrate the processing board and improve the drilling quality. It is an indispensable drilling auxiliary material for PCB mechanical drilling.

At present, mechanical drilling and laser drilling are often used in the through-hole of PCB. Generally, mechanical drilling is used in the through-hole with an aperture of 0.1mm or more, while laser drilling is used in the blind hole with an aperture of 0.1mm or less.

In the early stage of PCB drilling, the main function of the Backup board is to run through the processing board and protect the processing board and drilling machine. With the development of PCB drilling technology and the improvement of demand, PCB Drilling engineers have gradually found that different materials and quality of the backing plate have different auxiliary effects on drilling performance, such as reducing the falling edge, improving the accuracy of the hole, reducing the residue of drilling cuttings, reducing the wear and temperature of the drilling needle, cleaning the drilling needle, etc.

The researchers studied the drilling performance of PCB on the commonly used drilling pads in the current market: high density wood fiber board, UV plain board, phenolic wood pad, melamine wood pad (including cold paste type, fast press type, hot press type), phenolic paper pad, and compared the impact of different types of pads on the drilling performance of different apertures.

The final conclusion is that for the small pore size of 0.15mm and 0.20mm, the properties of the backing material have a great impact on the drilling performance. With the increase of the hardness and density of the backing material, the drilling performance is greatly improved; for the large pore size of 0.35mm, the properties of the backing material have a weaker impact on the drilling performance, and the hardness and density of the backing material have almost no significant impact on the drilling performance。

As the hole diameter becomes smaller and the drill bit becomes small, the drilling speed increases and the drill bit swinging frequency increases; at the same time, the finer the drill bit, the worse the positioning effect of the backup board on the drill bit; in addition, the finer the drill bit, the PCB The drilling depth of the backup board set in the plant becomes shallow, and the positioning effect is affected accordingly. Therefore, increasing the hardness and density of the backup boar is more conducive to improving the positioning effect of the drilling needle, thus improving the hole position offset and accuracy of the drilling, and the increase of the surface hardness and density of the backup board can effectively inhibit the generation of the drape.