admin

admin  January 21,2026

January 21,2026

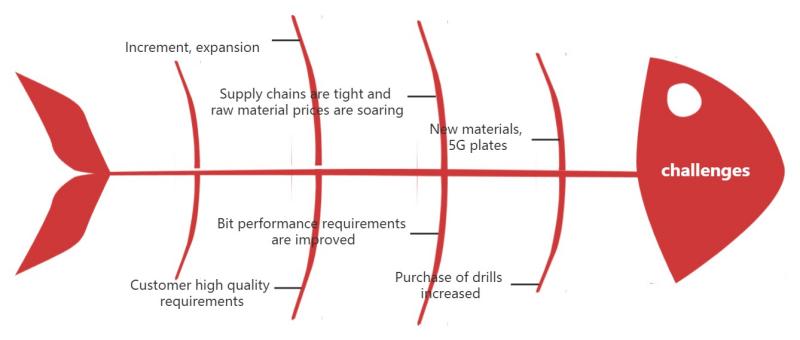

Under the background of 5G and Material rising sound, pcb manufacture how to upgrade the drills and reduce cost and increase efficiency?

Due to the ceramic filler plate (such as 5G base station high frequency plate) added ceramic powder (such as alumina, silica, etc.) in the substrate,

hardness is much higher than the carbide material used in ordinary drilling needle, resulting in extremely easy wear of ordinary drilling needle,

greatly reduced life, processing efficiency reduction, processing quality deterioration.

At present, the best solution is to use super-hard nano-diamond coating drilling needle, combined with special structure design,

to achieve a drilling life of tens of times the effect, excellent wear resistance, greatly improved quality,

perfect solution to the ceramic plate processing problems.