admin

admin  January 21,2026

January 21,2026

Most of the PCB manufacturers are facing these problems when producing HDI boards and BGA (1)

The first problem is Hole position accuracy

if the hole position accuracy not well,it may cause plug-in offset and unable to weld

so how to improve the hole position accuracy is a question that every PCB manufacture need to think about!

as we know Many factors can affect the results of drilling,Especially the following ones.

and this is also we want share with you today Lubrication aluminum entry sheet. how they can improve the hole position accuracy?

1. When the bit touches the lubricated aluminum boards while drilling, the polymer resin on the boards can stabilize the bits instantly

when the bit contacts the surface and reduce deviation.

2. The temperature of a bit drilling lubricated Aluminum boards is much lower than drilling normal Aluminum board.

The cooler the bit is, the more hard it is and the less it is to bending. Therefore, using lubricated Aluminum board can improve the the

hardness of the bit while drilling, so improve accuracy.

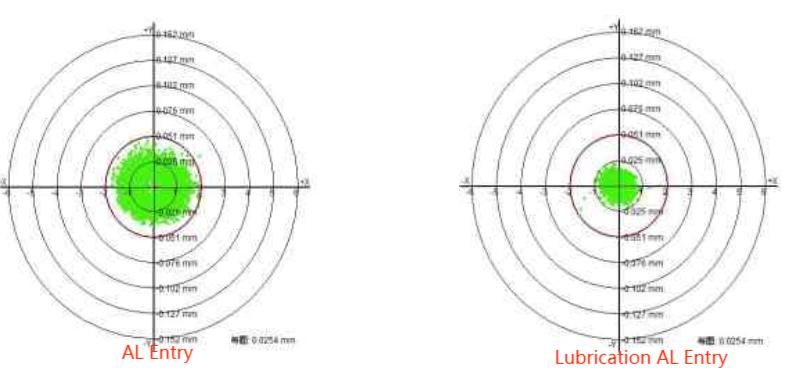

following picture shows the CPK of using 2 types of entry board.